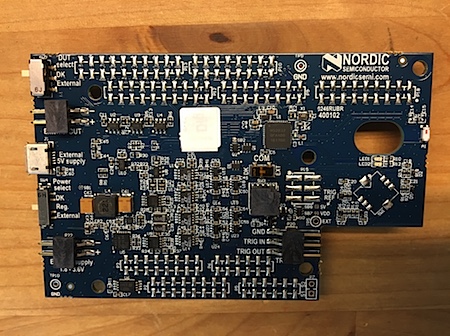

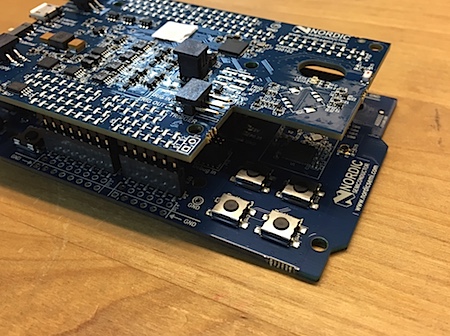

Finally received my Nordic PPK. I've only used this a little bit, but so far it's a fantastic tool for measuring the current consumption of Nordic parts / boards / modules.

Posted by: Lab Coat

| @ February 1, 2017 2:23:50 PM CST ( ) |

Last year I decided that I needed a better (easier / lazier?) way to control watering around the farmstead. Did I ever mention that we have an Urban Farm? See here ... https://www.facebook.com/3acresandabarn/

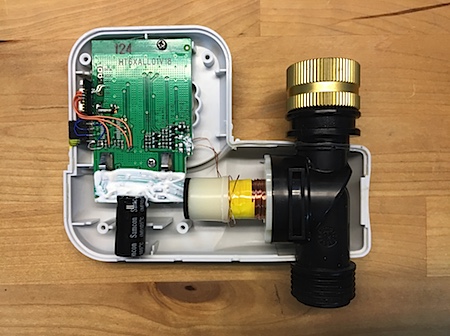

Back to our regular program ... So I purchased a couple of inexpensive Orbit water valves with timers, and did what any self-respecting engineer would do ... I gutted them! Seriously though, I removed the Cypress MCU that was on the board and swapped in an nRF51822 BLE part (via an rfDuino RFD22301 module). After al little coding on both the Nordic part and a complimentary iOS app, I had a remotely controllable water valve. Sweetness.

This year (2017) I plan to go all out with the Farm-tronics stuff. I have a camera setup ready to go for the chicken coop (RPi and camera), and several soil sensors ready to go into our various garden beds. Not 100% sure how all of this will come together in the end, so stay tuned. We'll use these water valve for some drip / soaker applications to better control moisture in the beds.

Pics...

Front / outside...

Rear / outside... (dark gray portion is the battery holder ... 2AAs)

Inside (water valve on the right is a latching type so there isn't a constant high-level battery drain)...

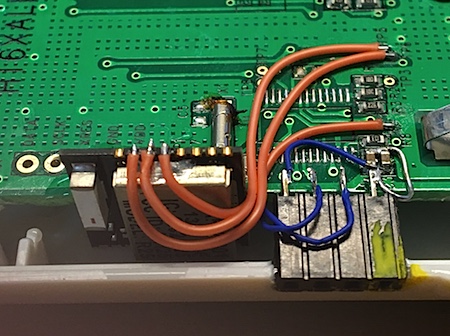

Closeup of the RFD22301 module and my 4 pin programming port. I do not use DFU (partially on purpose), so I need a way to program parts in-circuit. This is how I do it...

Posted by: Lab Coat

| @ January 9, 2017 3:58:27 PM CST ( ) |

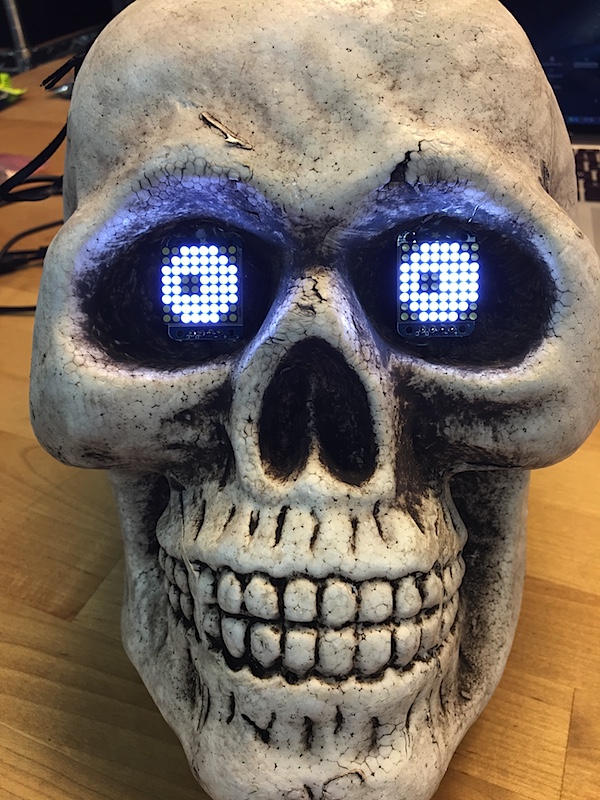

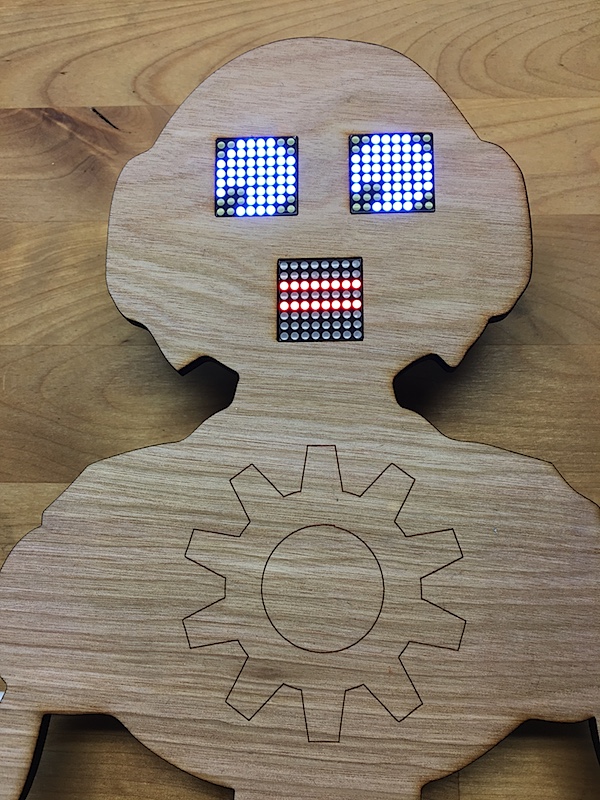

I did this proof-of-concept demo piece in October of last year for TechShop here in St. Louis. The eyes were animated ... it was fun.

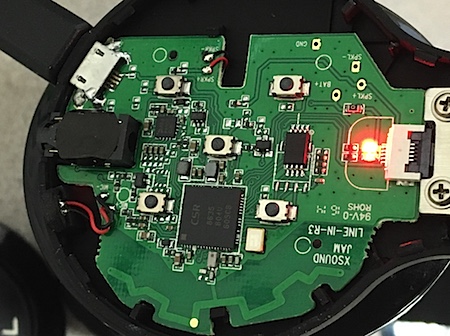

Guts...

In operation...

Posted by: Lab Coat

| @ January 9, 2017 3:25:38 PM CST ( ) |

My wife and I were recently talking, and I said that I wanted to start a website called Crappy Chinese Manufacturing. She admonished me by stating that such websites already exist. They're called D.... and F... B..... Redact that please.

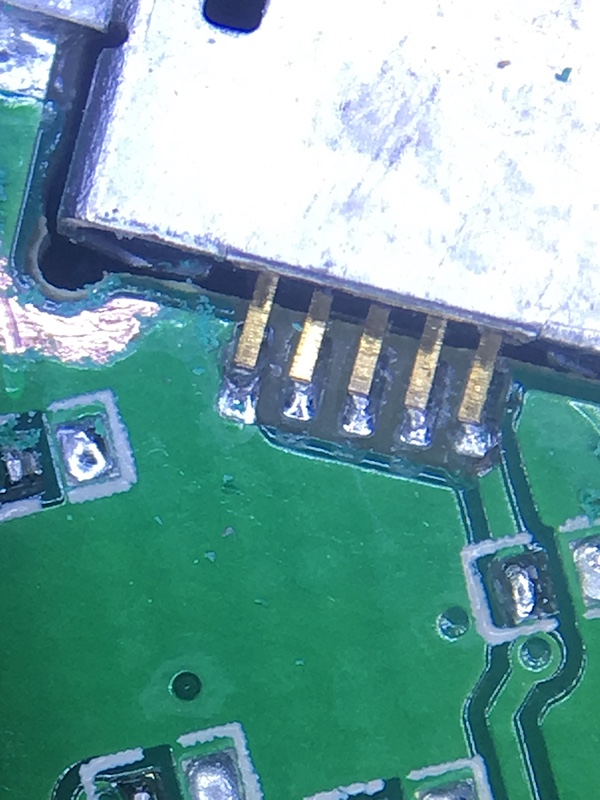

Here's a prime example, except these were not cheap headphones. And yet they broke less than a month after we purchased them. Albeit young boys are hard on stuff, but come on ... a month! Failure mode was a lack of charging.

This is the main board, and that shiny thing is the USB micro connector. You may notice that the 2 pins on the ends of the connector have broken free from the board (let's call them pins #1 and #5). As one would plug in, or unplug, the USB cable, one might put lateral stress on the connector, thus breaking the connections. The cheap manufacturer couldn't spare the few extra pennies to buy an appropriate connector that had mechanical support at both the front AND rear.

So I took the time to scrape the solder mask and mechanically attach the back end of the connector to the board. In the past 4 months, we've had no new failures. By the way, they used CSR for their bluetooth chipset.

Posted by: Lab Coat

| @ January 9, 2017 3:16:39 PM CST ( ) |

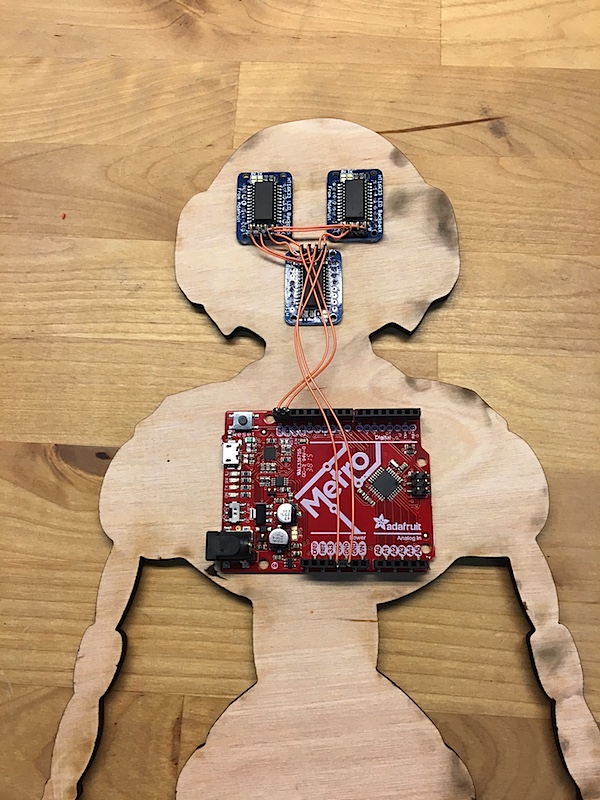

I helped with the electronics portion of this proof-of-concept project in December of last year for TechShop here in St. Louis. It was fun.

Robby without any guts...

Click to embiggen (~2.5MB)

Wiring side...

Click to embiggen (~2.5MB)

In operation...

Click to embiggen (~3.5MB)

Posted by: Lab Coat

| @ January 9, 2017 3:02:29 PM CST ( ) |

Previous 1 2 3 4 5 Next

|

|